-

Mercedes-Benz gibt Gas: Sauber und leise durch die City

-

Leichte und stabile Gasflaschen aus Compositmaterial

-

Weniger Gewicht bedeutet mehr Fahrgastplätze

-

Neuer Gasmotor M 936 G: Paradebeispiel für Downsizing

-

Saubere Verbrennung mit hoher Leistung und wenig Emissionen

-

Kraftstoffverbrauch sinkt um rund 15 bis 20 Prozent

-

Citaro weiterentwickelt: Mit LED-Scheinwerfern leuchtendes Vorbild

Die Nummer eins unter den Stadtlinienbussen wird jetzt noch attraktiver: Mit dem neuen Citaro NGT bietet Mercedes-Benz eine attraktive Alternative zum Citaro mit Dieselmotor an. Der Citaro NGT (Natural Gas Technology) besticht durch seinen leisen Lauf und reduzierte CO2-Emissionen – beides sind wesentliche Pluspunkte für den Verkehr in hochbelasteten Innenstädten. Praktiker überzeugt der Citaro NGT darüber hinaus durch sein niedriges Gewicht und entsprechend viele Fahrgastplätze, die kraftvolle Leistungsentfaltung des Motors, einen niedrigen Kraftstoffverbrauch und lange Wartungsintervalle. Mercedes-Benz bietet die neue Antriebsvariante sowohl als Solobus Citaro NGT sowie als Gelenkbus Citaro G NGT an. Der Citaro NGT kann sowohl mit Erdgas als auch mit Bio-Erdgas betrieben werden – dann fährt der Citaro NGT sogar annähernd CO2-neutral.

Mercedes-Benz gibt Gas: Sauber und leise durch die City

Mercedes-Benz Omnibusse gibt kräftig Gas: Der neue Citaro NGT mit Erdgasmotor setzt Maßstäbe in Sachen Umweltfreundlichkeit. Der Citaro NGT ist außerdem ohne Einschränkung für die Verwendung von Bio-Erdgas nach DIN 51624 freigegeben. Damit wird die CO2-Bilanz nochmals attraktiver, denn dann fährt der Erdgasbus sogar nahezu CO2-neutral.

Darüber hinaus unterschreitet der Citaro NGT das Geräuschniveau des bekannt laufruhigen und leisen Dieselmotors OM 936 über das gesamte Drehzahlband nochmals hörbar. Je nach Fahrzustand liegen seine Geräuschemissionen bis zu 4 dB(A) niedriger, das entspricht etwa einer Halbierung des subjektiv empfundenen Geräuschniveaus.

Beide Faktoren – geringe CO2-Emissionen sowie niedrige Geräusche – prädestinieren den neuen Citaro NGT speziell für den Einsatz in hochbelasteten Innenstädten sowie für das Befahren von Wohngebieten.

Spezialisiertes Marktsegment von rund 1000 Erdgas-Stadtbussen

Das Segment der Stadtbusse in Westeuropa beläuft sich auf durchschnittlich rund 10 500 Neuzulassungen im Jahr mit einem stabilen Niveau. Auf den hochspezialisierten Bereich der Stadtomnibusse mit Erdgasantrieb entfallen in Europa derzeit knapp 1000 Einheiten im Jahr. Mercedes-Benz rechnet damit, dass sich diese Zahl im Rahmen von Diskussionen über die Umweltbelastung in Ballungsgebieten oder Ressourcenschonung künftig weiter erhöhen kann. Allein durch das Angebot des neuen Mercedes-Benz Citaro NGT mit einem hochmodernen Erdgasmotor ist mit einer Belebung zu rechnen.

Erkennungsmerkmal ist die markante Abdeckhaube

Der Citaro mit Erdgasantrieb ist als Solobus Citaro NGT sowie als Gelenkbus Citaro G NGT lieferbar. Zu erkennen sind beide an der markanten Abdeckhaube für die Gasflaschen auf dem Dach. Durch sie steigt die Gesamthöhe der Erdgasbusse auf exakt 3389 mm. Die weiteren Maße sind gegenüber dem Citaro mit Dieselantrieb unverändert. Aus Gründen der Gewichtsverteilung sind die Gasflaschen beim Solobus über der Vorderachse und beim Gelenkbus über der mittleren Achse angeordnet.

Die Abdeckung besteht aus dem Kunststoff Polyurethan mit einem innen montierten Aluminiumrahmen. Sie ist über ein Schienensystem auf dem Dach befestigt, verfügt über eine seitliche Serviceklappe für den leichten Zugang zu den Flaschenventilen und ist zusätzlich komplett aufschwenkbar.

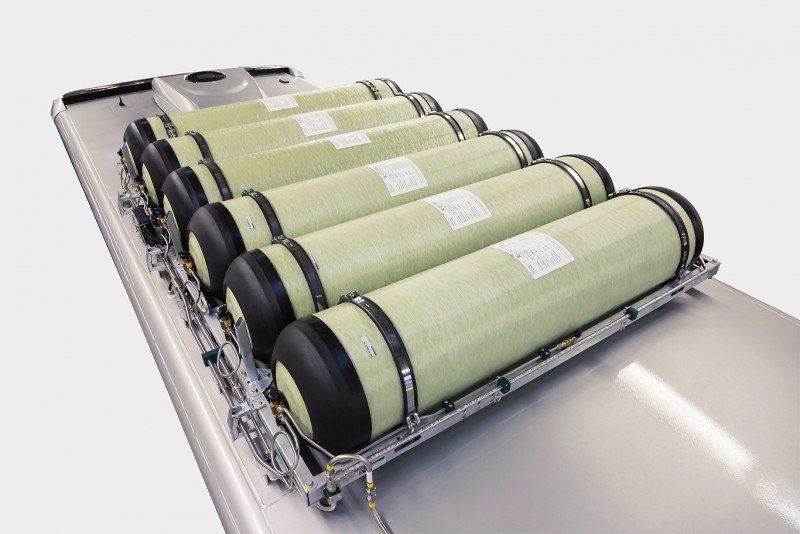

Leichte und stabile Gasflaschen aus Compositmaterial

Unter der Abdeckung ruhen die neu entwickelten Gasflaschen des Citaro NGT. Sie bestehen aus einem Compositmaterial mit Kunststoffkern, einer Ummantelung aus Kohlefasern sowie – neu – zusätzlich aus Glasfasern. Diese Werkstoffkombination ist einerseits sehr leicht und andererseits hochstabil. Die Betankung der Gasflaschen erfolgt serienmäßig im Motorraum des Omnibusses. Auf Wunsch wechselt der Einfüllstutzen über den Radlauf vorne rechts, das entspricht der Einfüllposition des Citaro mit Dieselantrieb.

Gleichzeitig wurde das Tankvolumen der neuen Generation deutlich von jeweils 190 l auf 227 l erhöht. Vorteil: Bei gleichem Gesamtvolumen kann deshalb die Zahl der Behälter reduziert werden. Im Vergleich zum Vorgängermodell kommt Citaro NGT bei unveränderter Reichweite daher jeweils mit einer Gasflasche weniger aus. Daraus resultiert ein spürbarer Gewichtsvorteil von 15 bis 45 kg, abhängig von der Zahl der Gasflaschen.

Diese wiederum kann einsatzspezifisch festgelegt werden. Zwei Haubenvarianten stehen zur Verfügung, sie nehmen je nach Bedarf vier bis sechs Gasflaschen bzw. sieben oder acht Gasflaschen auf. In der Praxis erreicht der Citaro NGT die gleiche Reichweite wie ein Citaro mit Dieselmotor.

Geringeres Mehrgewicht bedeutet mehr Fahrgastplätze

Das vor allem durch die Gasflaschen verursachte Mehrgewicht des Citaro NGT wird im Vergleich zum Vorgänger deutlich reduziert. Es wird sich bei einem Solowagen auf lediglich rund 485 kg belaufen. Neben der neuen Flaschenanlage ist dafür auch der deutlich kompaktere Motor verantwortlich.

Der Fahrgastraum des Citaro wird durch den Erdgasantrieb in keiner Weise beeinträchtigt. Im Gegenteil: Aufgrund der Gewichtsersparnis steigt die Fahrgastkapazität des Citaro NGT im Vergleich zum Vorgängermodell deutlich an. In Serienausstattung befördert der Solobus Citaro NGT nun bis zu 96 statt bisher 93 Passagiere. Der Gelenkbus Citaro G NGT nimmt sogar maximal 153 statt bislang 149 Fahrgäste auf.

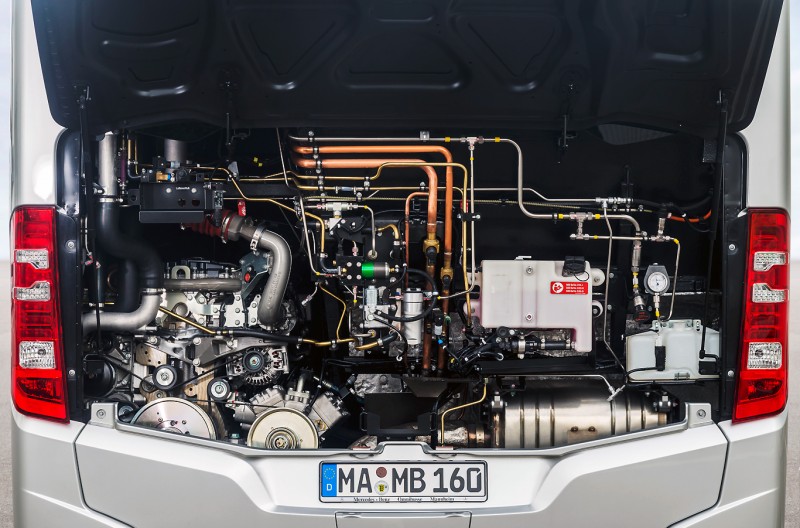

Neuer Gasmotor M 936 G: Paradebeispiel für Downsizing

Beim neuen Erdgasmotor Mercedes-Benz M 936 G mit 7,7 l Hubraum handelt es sich um den derzeit kompaktesten Erdgasmotor seiner Klasse. Er erreicht die Performance eines Dieselmotors und setzt gleichzeitig Maßstäbe in Geräusch und Abgasemission. Der Motor ist besonders kompakt und leicht: Mit einem Gewicht von nur 747 kg einschließlich Vorkatalysator wiegt er rund 230 kg oder knapp 25 Prozent weniger als das Vorgängertriebwerk mit 12,0 l Hubvolumen – das Triebwerk ist damit ein Paradebeispiel für erfolgreiches Downsizing.

Der Erdgasmotor Mercedes-Benz M 936 G basiert auf dem hochmodernen Turbodieselmotor OM 936. Dieser wird bereits erfolgreich im Citaro und Citaro G Euro VI eingesetzt. Der stehend eingebaute Reihensechszylinder wird als monovalenter Motor mit komprimiertem Erdgas betrieben (CNG = Compressed Natural Gas). Er leistet 222 kW (302 PS) bei 2000/min, erreicht ein maximales Drehmoment von 1200 Nm konstant von 1200 bis 1600/min und unterschreitet die Abgasgrenzwerte von Euro VI zum Teil erheblich.

Erdgastriebwerk so kraftvoll wie ein Diesel und noch sauberer

Mit diesen Daten sowie mit seiner kraftvollen Leistungsentfaltung ist der einstufig aufgeladene Motor seinem Pendant mit Dieselantrieb völlig ebenbürtig. Die Leistungs- und Drehmomentkurven verlaufen im Hauptfahrbereich von Leerlaufdrehzahl bis etwa 1500/min deckungsgleich. Oberhalb arbeitet der Erdgasmotor sogar einen leichten Leistungs- und Drehmomentvorteil heraus. Erst bei Drehzahlen über 2000/min ist der Diesel- dem Erdgasmotor überlegen – Regionen, die ein Stadtbus in der Praxis nicht erreicht.

Gleichzeitig setzt der Erdgasmotor von Mercedes-Benz die Messlatte für Umweltfreundlichkeit besonders hoch, denn die CO2-Emissionen eines Erdgasmotors liegen bis zu 20 Prozent unter denen eines Dieselmotors. Bei Verwendung von Bio-Erdgas wird diese CO2-Bilanz nochmals attraktiver, dann fährt ein Erdgasbus nahezu CO2-neutral.

Individuell auf Erfordernisse des CNG-Betriebs abgestimmt

Zylinderblock und der Vierventil-Zylinderkopf des M 936 G wurden vom Dieselmotor übernommen und an den Betrieb mit Erdgas angepasst. Neu entwickelt sind Aufladung, Ladeluftführung, Zündung und Gemischaufbereitung inklusive der wassergekühlten Abgasrückführung. Die Zündung eines Erdgasmotors entspricht einem Benzinmotor. Beim M 936 G finden Zündkerzen mit Stabzündspulen Verwendung. Sie sind in dem Bauraum untergebracht, wo bei Dieselmotoren die Injektoren der Kraftstoffeinspritzung ihren Platz haben. Die Kolbenmulde hat eine neue Geometrie erhalten.

Saubere Verbrennung mit hoher Leistung und wenig Emissionen

Der Erdgasmotor arbeitet mit einer stöchiometrischen Verbrennung von Lambda = 1 wie ein moderner Benzinmotor. Das bedeutet: Es ist genau die notwendige Luftmenge vorhanden, um den Kraftstoff vollständig zu verbrennen. In diesem Bereich erreicht auch der Katalysator seine maximale Reinigungsleistung. Daraus resultiert beim M 936 G eine besonders saubere Verbrennung bei gleichzeitig hoher Leistung und niedrigen Schadstoffemissionen. So sinken zum Beispiel durch das neue Brennverfahren die NOx-Emissionen im Vergleich zum Vorgänger erheblich.

Ein Turbolader mit asymmetrischer Turbinengeometrie und zwei Wastegate-Ventilen sichert gutes Ansprechverhalten des Motors und gleichzeitig die Versorgung der gekühlten Abgasrückführung. Aufgrund der praktisch rußfreien Verbrennung entfallen sowohl die vom Dieselmotor gewohnte SCR-Technik mit AdBlue-Einspritzung als auch der Partikelfilter. Die Abgasreinigung übernimmt beim Gasmotor wie bei einem Ottomotor ein Dreiwegekatalysator. Er setzt sich aus einem Vorkatalysator mit zwei Lambdasonden sowie einem Hauptkatalysator zusammen.

Der neue Erdgasmotor M 936 G hat sich bereits seit einem Jahr im Verteiler- und Entsorgungsfahrzeug Mercedes-Benz Econic bewährt. Der Grundmotor für den Citaro NGT ist identisch. Aufgrund der unveränderten Grundmaße zum Ausgangsmotor Mercedes-Benz OM 936 ist das Packaging im Heck des Citaro weitgehend gleich. Für die andere Einbaulage mussten lediglich Komponenten wie Ölwanne und Riemenantriebe sowie Wasserstutzen, Luftpresser, die Hydraulikpumpe des Lüfters und Luftleitbleche angepasst werden – übliche Adaptionen für einen Omnibusmotor.

Kraftstoffverbrauch sinkt um rund 15 bis 20 Prozent

Der neue Hightech-Erdgasmotor arbeitet extrem effizient. Zusammen mit einer intelligenten Ansteuerung der Nebenaggregate resultiert daraus ein Einsparpotenzial des Citaro NGT gegenüber dem Vorgängermodell von rund 15 bis 20 Prozent. In Verbindung mit dem optionalen Rekuperationsmodul sind sogar noch größere Einsparungen zu erwarten.

Die Intervalle für den Wechsel von Motoröl und Zündkerzen konnten im Vergleich zum Vorgängermotor erheblich von 45 000 km auf 60 000 km verlängert werden. Bei diesem praxisgerechten Maß muss der Citaro NGT bei einer für Stadtbusse üblichen Laufleistung von rund 60 000 km im Jahr damit lediglich ein Mal per anno zum Service.

Wandler-Automatikgetriebe auf die Motorcharakteristik abgestimmt

In gewohnter Weise übernehmen Wandler-Automatikgetriebe der beiden Fabrikate ZF und Voith die Kraftübertragung. Sowohl die Schaltpunkte als auch der Einsatz des Wandlers wurden speziell auf die Motorcharakteristik des neuen Gasmotors angepasst. Gleiches gilt für die zur Verfügung stehenden Achsübersetzungen. Aufgrund des anderen Drehzahlniveaus haben die Entwickler die serienmäßigen Achsübersetzungen im Vergleich zum Dieselmotor durchweg eine Stufe kürzer ausgewählt, also i = 6,19 für den Solobus und i = 6,98 für den Gelenkbus.

Bei Kälte, Hitze und Höhe ausgiebig getestet

Der neue Citaro NGT erfüllt von Beginn an höchste Ansprüche – auch an die Zuverlässigkeit. Dafür haben die Entwicklungsingenieure ihn drei Jahre lang intensiv unter härtesten Bedingungen erprobt. Dazu zählten Wintererprobungen in Skandinavien bei beißender Kälte ebenso wie Sommererprobungen in Mailand sowie in Sölden/Tirol. Dort wurde der Citaro NGT gleichzeitig bei einer Höhenerprobung bis 1600 m über Meeresspiegel getestet. Hinzu kam ein Dauerlauftest. Hinter den Erprobungen steht auch eine logistische Leistung, denn nicht in jedem der klassischen Testgebiete ist eine Versorgung mit Erdgas gesichert. Die drei Erprobungsfahrzeuge legten insgesamt rund 130 000 km erfolgreich zurück. Die Auslieferungen des neuen Citaro NGT beginnen bereits im Herbst 2015. Der volle Serienanlauf erfolgt im Frühjahr kommenden Jahres.

Citaro NGT – durch und durch ein echter Citaro

Mit über 7000 Fahrzeugen seit der Vorstellung im Jahr 2011 hat die aktuelle Baureihe des Citaro den einmaligen Erfolg des Vorgängermodells nicht nur weitergeführt, sondern sogar noch ausgebaut. Die Basis dafür liegt in den herausragenden Eigenschaften des Niederflur-Stadtbusses.

Augenfällig ist sein freundliches Gesicht mit großen mandelförmigen Scheinwerfern und einem runden Vorbau. Dahinter verbirgt sich ein Crash-Element zum Schutz des Fahrers. Ohnehin ist der Rohbau besonders steif und damit sicher und trotzdem leicht. Die seitliche Fensterlinie liegt tief, dreidimensional geformte Radläufe aus GfK verleihen der Karosserie Spannung. Zusammen mit der Einführung der Dieselmotoren für Abgasstufe Euro VI wurde im Jahr 2012 das Heck neu gestaltet.

Die Einstiege des Citaro NGT sind mit 320 mm an allen Türen niedrig, der Fahrgastraum besticht mit Helligkeit und Freundlichkeit. Ob Lichtkonzept oder ovale Haltestangen – der Citaro ist bis ins Detail durchdacht. Gleiches gilt für das höher gelegte Cockpit mit hinten angeschlagener Tür und einer ergonomisch perfekten Instrumentenanlage. Premiere für Niederflur-Stadtlinienbus hatte im Citaro das optional lieferbare Elektronische Stabilitätsprogramm ESP. Eine Vielzahl von Maßnahmen senkt den Kraftstoffverbrauch und die Wartungskosten.

Ob abgesenkte Einstiege, geregelter Luftpresser oder eine Erhöhung des Systemdrucks für Federung und Türbetätigung. All dies senkt den Kraftstoffverbrauch. Herausragend ist das einzigartige Rekuperationsmodul: Doppelschichtkondensatoren – so genannte Supercaps – dienen zusätzlich zu den Batterien als Zwischenspeicher von Strom. Sie unterstützen damit das aktive Batterie-/Generatormanagement.

Aktuelle Weiterentwicklungen: Mit LED-Scheinwerfern leuchtendes Vorbild

Der neue Citaro NGT profitiert darüber hinaus in vollem Umfang von den jüngsten Weiterentwicklungen des Citaro. Neu ist die optionale Ausstattung mit LED-Hauptscheinwerfern. Der Lichtkegel von LED-Scheinwerfern ist besonders präzise definierbar. Ihre Lichtfarbe entspricht etwa dem Tageslicht und lässt die Augen des Fahrers daher weniger schnell ermüden. LED-Lampen sind etwa zwei- bis dreimal effizienter als herkömmliche Glühlampen und senken deshalb den Stromverbrauch spürbar. Nicht zuletzt erreichen sie Fahrzeug-Lebensdauer, ein Wechsel des Leuchtmittels ist deshalb in der Regel nicht mehr notwendig.

Im Citaro kommt ebenfalls eine neue Generation Klappsitze zum Einsatz. Sie sind aufgrund ihrer größeren Breite jetzt als vollwertige Sitze in den Zulassungspapieren eintragbar. Ihre Optik ist an das Design des Citaro angepasst. Die Klappsitze sind als Einzelsitze sowie – neu – ebenfalls als Mutter-und-Kind-Sitz sowie als Doppelsitz erhältlich. Die Klappsitze werden entweder auf einem Gestell in oder gegen die Fahrrichtung montiert oder an der Seitenwand.

Der Citaro NGT erhält ebenfalls die neue Elektronikarchitektur des Citaro. Zu erkennen ist sie am großen und farbigen Display in der Instrumentenanlage, an neuen Tasten sowie dem ebenfalls neuen Bedienteil für Heizung, Lüftung und Klima.

Nicht zuletzt profitiert der Citaro G NGT wie jeder Citaro Gelenkbus von der neuen Knickwinkelsteuerung ATC (Articulation Turntable Controller). ATC setzt einen neuen Standard für Fahrdynamik und Sicherheit bei Gelenkbussen: Die fahrdynamische Steuerung ATC regelt die hydraulische Dämpfung des Gelenks schnell und vor allem bedarfsgerecht, abhängig unter anderem von Lenkwinkel, Knickwinkel, Geschwindigkeit und Last.

Gerät der Gelenkbus in einen instabilen Zustand, wird die Dämpfung des Gelenks schnell und bedarfsgerecht eingesteuert. Damit wird der Gelenkbus im Rahmen der physikalischen Möglichkeiten sehr schnell stabilisiert. Die Knickwinkelsteuerung ATC erzielt auf diese Weise annähernd den Effekt einer elektronischen Stabilitätsregelung. Beim üblichen stabilen Fahrzustand läuft das Gelenk dagegen nahezu frei und wird allein durch die Reibung der Elemente gedämpft. Somit sind Eigenlenkverhalten und Lenkarbeit optimiert und der Reifenverschleiß an der Vorderachse minimiert. Ansprechverhalten und Lenkkräfte des Gelenkbusses entsprechen nahezu einem Solofahrzeug.

Das Ausstellungsfahrzeug im Detail

Auf der Messe Busworld Kortrijk präsentiert Mercedes-Benz den Citaro NGT als Solobus mit zwei doppeltbreiten Türen. Fahrzeug und Anbauteile sind in Brillantsilber-Metallic lackiert. Dies gilt ebenfalls für die Abdeckhaube der Gasflaschen, hier in der großen Ausführung mit sieben Flaschen und 1589 l Volumen für eine besonders große Reichweite. Die Vorderachse ist mit einer zulässigen Achslast von 7,5 t entsprechend angepasst. Die Kraftübertragung des Erdgasmotors Mercedes-Benz M 936 G übernimmt ein Wandler-Automatikgetriebe von Voith. Ein Rekuperationsmodul minimiert den Kraftstoffverbrauch.

Das Ausstellungsfahrzeug verfügt über LED-Scheinwerfer. Zur weiteren Sicherheitsausstattung gehören unter anderem das elektronische Stabilitätsprogramm ESP, ein Regen-/Lichtsensor, eine Reifendruckkontrolle sowie eine Brandlöschanlage. Der Sicherheit dient ebenfalls eine umfangreiche Videoanlage mit vier Kameras zur Beobachtung der beiden Einstiege sowie des Fahrgastraums.

Der Fahrerplatz ist mit elektrischer Betätigung von Außenspiegeln, Fahrerfenster und Sonnenrollo komfortabel ausgestattet. Die Tür zur Fahrerkabine verfügt über eine integrierte Zahlkasse. Sowohl der Fahrerplatz als auch der Fahrgastraum sind klimatisiert. Die Fahrgäste nehmen auf der Bestuhlung City Star Eco mit einem komfortablen Stoffbezug Platz. Außerdem stehen ihnen im Bereich des Rollstuhlplatzes sowie auf der Sondernutzungsfläche Klappsitze zur Verfügung. Mit Haltestangen in Pastellorange, Deckenhandläufen in Evo Steel sowie einem Bodenbelag in Gaya Wood darkbrown ist der Fahrgastraum des Citaro NGT gleichermaßen funktionell und wohnlich eingerichtet.

Text und Bild von Daimler Buses Pressemitteilung

Bearbeitet von Wonho Choi

Update am 10. Sept. 2015

![[Weltpremiere] Der Mercedes-Benz Citaro NGT](/data/file/articles/654783679_MHV3IEn9_citaro_ngt_01.jpg)

Kein Kommentar / There is no comment / 댓글은 힘이 됩니다.